Maximize Your Profitability with TA Systems Industry 4.0 Enterprise Profit Improvement (EPI™) System

TA System’s applies over 45 years of expertise and best-of-breed software solutions in all phases of an automated assembly systems lifecycle to deliver on value propositions related to Industry 4.0 and beyond to Industry 5.0. We are not only experts in designing, building, and installing automated assembly systems but also at providing our customers with automation solutions that realize the benefits associated with Industry 4.0, AI and Machine Learning by maximizing profitability.

Industrial Intelligence with Real Time Data Visualization for Manufacturers

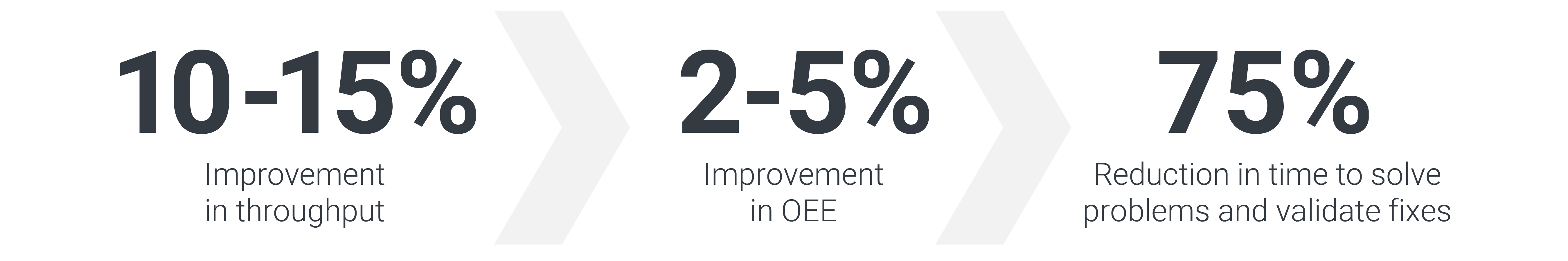

WITHIN A FEW WEEKS OF EPI™ INSTALL, OUR CLIENTS EXPERIENCE

We understand manufacturing, and our ability to not just obtain crucial real time data but to translate the data into viable solutions and see them through implementation makes EPI™ a must-have team member.

Identify Opportunities with Trustworthy Big Data and Advanced Analytics

By leveraging data effectively and employing advanced analytics techniques, our clients can uncover hidden opportunities, optimize processes, drive operational efficiency to make informed decisions and drive meaningful improvements throughout the manufacturing ecosystem.

- Unprecedented End-to-End Value Realization

- Increase in Throughput

- Detection of Manufacturing Potential

- Identification of Spare Capacity

- Predictive Process

- Enterprise & Supplier Process Visibility

- Skilled Trade Shortage Mitigation

Performance Tuning

TA Systems HQ

- Hardware debug

- Functional debug

- Performance debug

- Establish machine performance baseline

Benefits: Performance optimization and target rate validation

On-Site Launch

Customer Plant

- Equipment set-up

- Initial cycle

- Dry cycle

- Confirm machine performance

- Leverage remote support capability

Benefits: Reduction in NPI, Prove system is ready for parts, Run-at rate-validation

Production

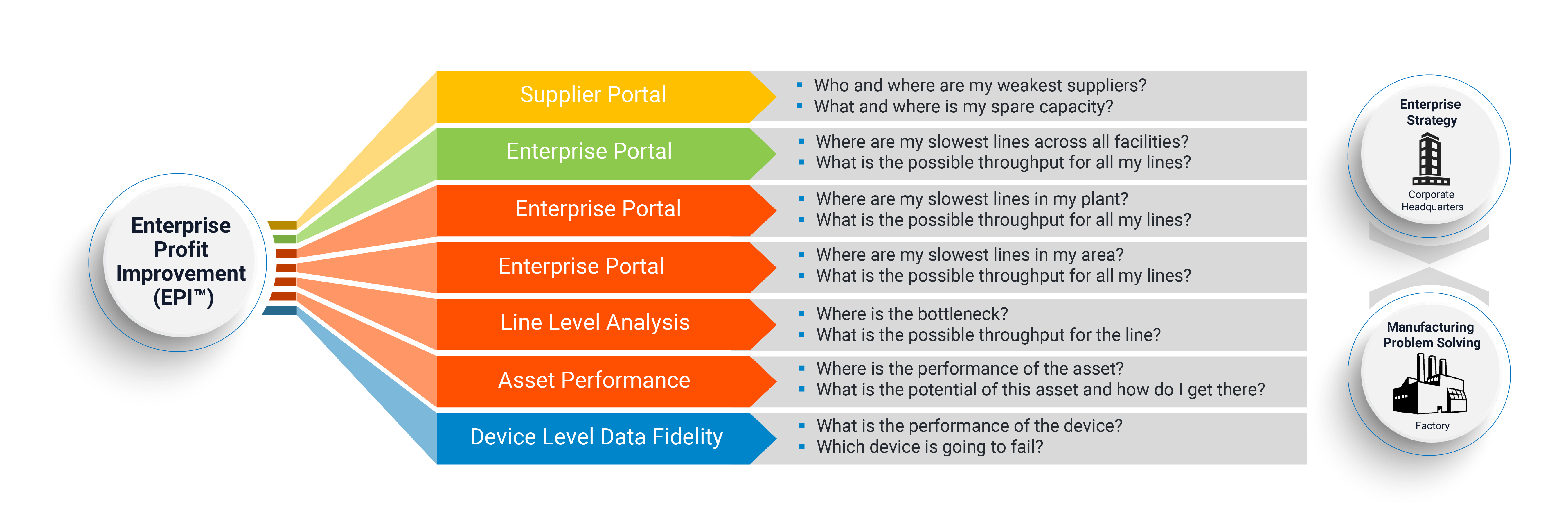

What our EPI™ System will help you determine

Predictive Support & Profit Realization

Service + IIoT = Value-Added Solutions

- Proactive Monitoring Service

- Monthly Analysis with Profit Improvement Recommendations

- Quarterly Initiatives Plan

- Predictive vs Reactive Results

- Improvement Execution Services:

- Technical support

- Re-tool

- In-plant services

- Spare parts management

- Hardware fixes

- Performance based predictive maintenance

How Your Business Will Benefit by Using Our Industry 4.0 EPI™ System

Maximizing Profitability

- Unprecedented performance optimization, bottleneck elimination, and predictive maintenance can be achieved Through Non-traditional KPI’s such as Potential OEE, Potential Cycle Time and Potential Throughput combined with the data depicting the detailed steps within a device

Optimize Production – The Plant, Area, Line, & Asset Level Data Visibility

- Enhance production by monitoring the traditional manufacturing KPI’s such as OEE, Cycle Time, and Throughput

Global Visibility of Plant Performance

- Identify potential production issues & ability to direct resources where needed

- Enterprise data visibility is an enabler in promoting best practices through a comparison of each individual plant’s production performance

Manufacturer & Supplier Data Sharing

- The Supplier Portal provides data sharing alignment between manufacturer and supplier – jointly view inventory levels, consumption rates, and in transit supply to effectively manage the ebbs and flows of production schedules, mitigate the volatility of a dynamic production environment, and proactively allocate resources when and where needed

Leverage TA Systems’ Experts

- Staying abreast of the latest technological advancements with our expert proficiency in deploying Industry 4.0 & AI solutions

- Proactively monitor the production performance of its customers and offer improvement recommendations on a reoccurring basis. This service offering is unique and overcomes the resource constraints and shortage of expertise often times associated with failed Industry 4.0 initiatives

- Help mitigate constraints associated with ever-increasing skilled labor shortage

Enable Industry 5.0

- Through the implementation of AI and Machine Learning based on trustworthy big data