Ultrasonic Welding

Totally Automated Systems brings over 40 years of expertise in the design and manufacturing of Sonic Welding Systems for customers in the Automotive & Non-Automotive Industry. TA Systems is committed to leading the Automated Robotic Assembly industry in technology and development. As a result, we offer our clients our Perfect Net-Out Patent Pending Technology which provides our customers with unsurpassed Robotic Systems for their needs.

Ultrasonic Welding is the use of high frequency vibration that generate heat and result in the bonding of materials. As the most common application of Ultrasonic Assembly, this welding process of creating frictional heat between parts that solidify and result in the production of a strong reliable joining of materials.

The versatility of ultrasonic assembly is an advantage to customers due to the tooling and application flexibility. Ultrasonic Welding can be used over a variety of materials including plastics (hard and soft) and softer metals. In fact, it surpasses traditional welding due to less distortion in materials such as aluminum and copper.

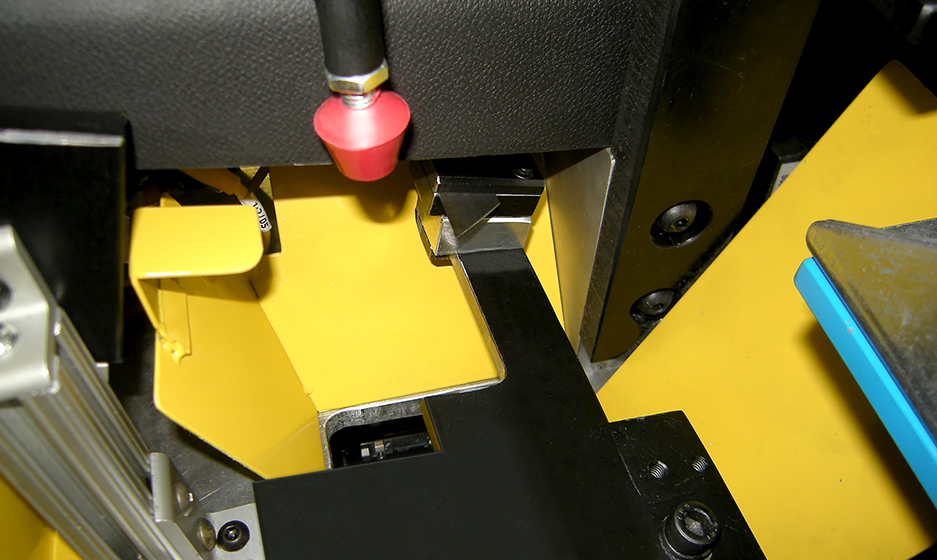

- Lower Warranty Risk as a result of Reduced Squeaks and Net Out Every Time

- Superior Sonic Performance through: Maximized Cooling, Ultrasonic Frequency Consistency, and finally Faster Cool Down

- Lower Cost/Improved Accessibility by eliminating: Clamp Plate and Hold Down as well as delivering Lower Cycle Times

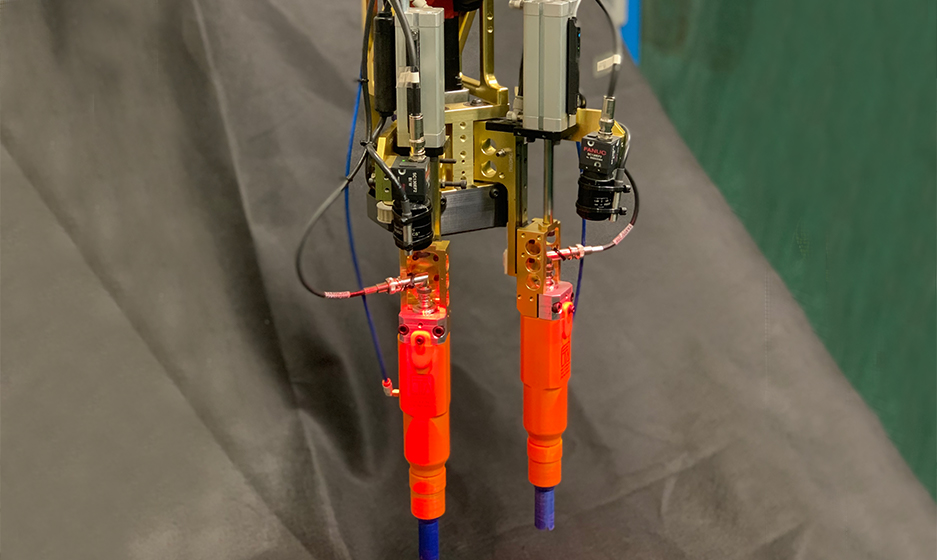

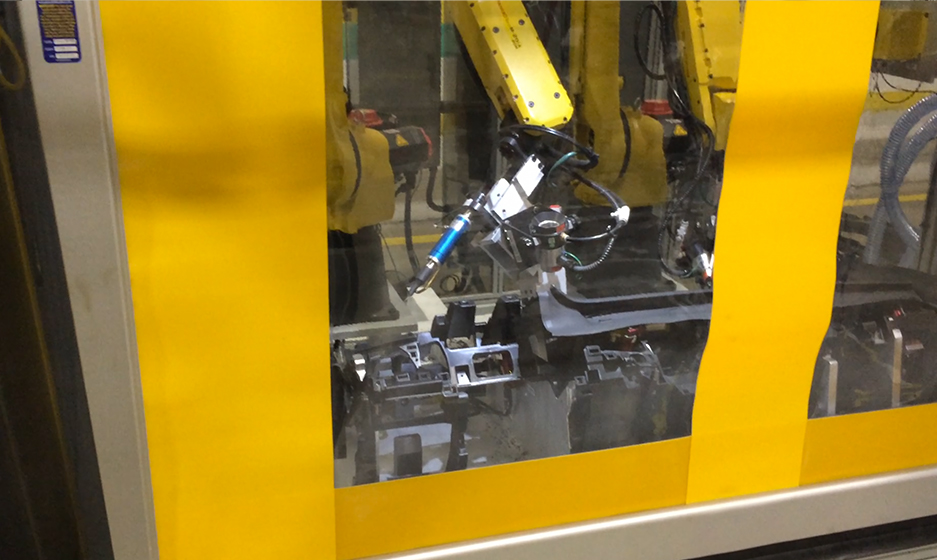

- TA Systems Standard Sonic Welding System Designs (Pictured) offer the following options: 2-Sided for Operators and 3-Sided for Operator Load (Pictured)

- Includes Spot and Stake Sonic Welding, Riveting of Steel Parts, Heavy Duty Construction and finally Robotic Load & Unload

Ultrasonic Welding is used in a variety of assembly categories including:

- Assembly Lines

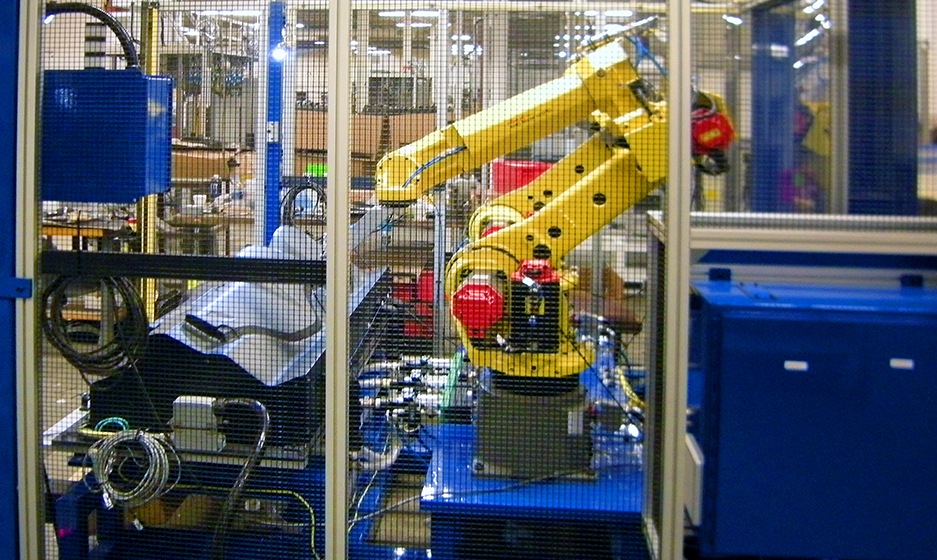

- Dedicated Equipment

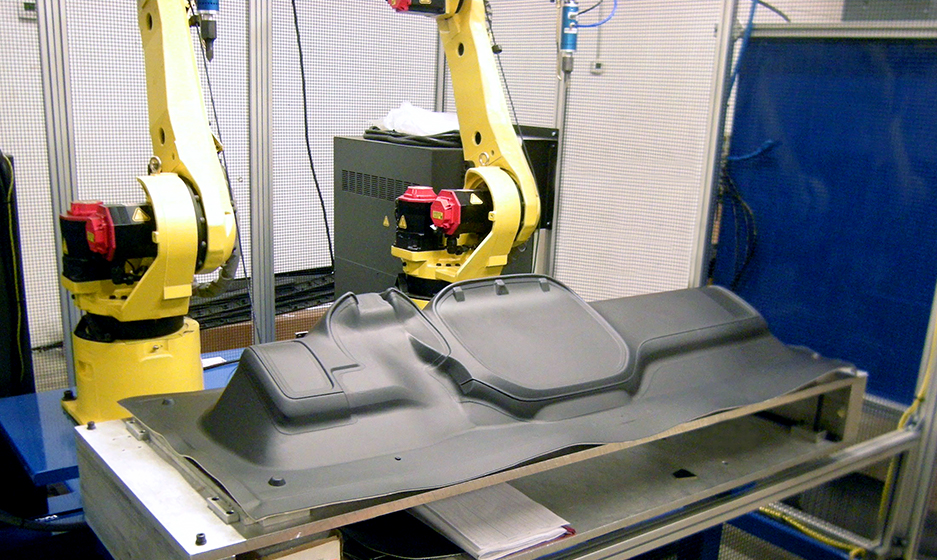

- Robotic Dedicated Equipment

- Robotic Flexible Equipment

- Tool Exchange Equipment

Ultrasonic Welding is used in a variety of assembly applications including:

- Manual Workstations

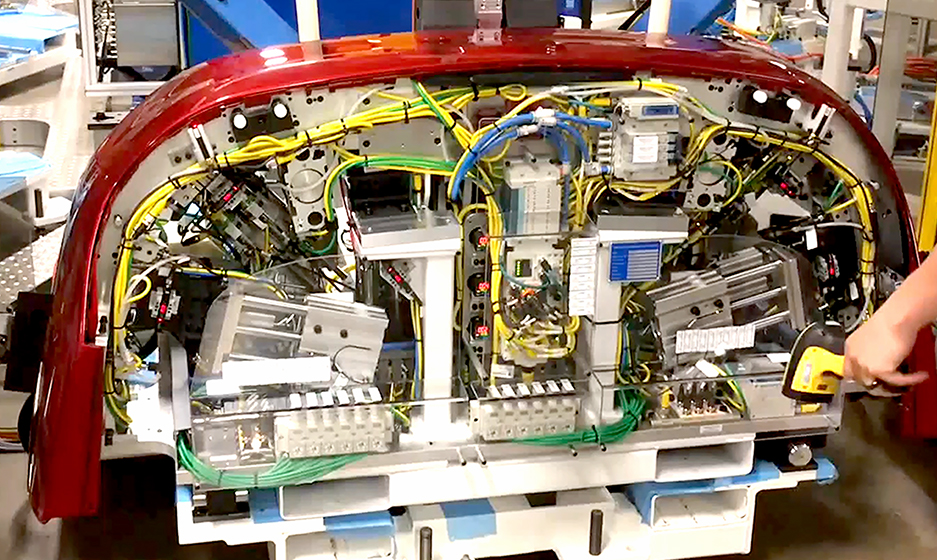

- MES/FIS/QIS

- Traceability

- Welding

- Automotive Interior

- Automotive Exterior

- Non-Automotive