Maximize Profitability Through Innovative Automation

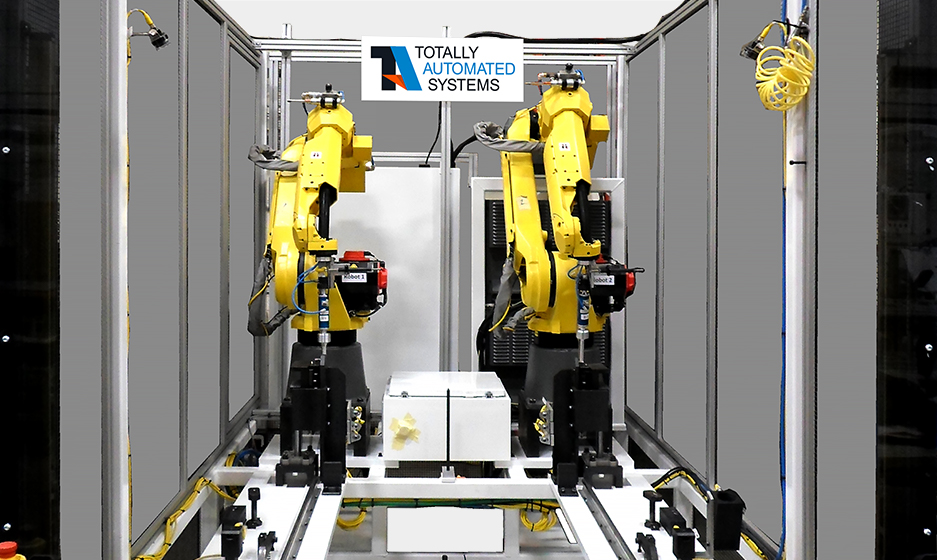

Totally Automated SYSTEMS BRINGS OVER 45 YEARS OF EXPERIENCE IN AUTOMATED ASSEMBLY SYSTEMS.

The TA Systems team prides itself on cradle to grave customer support and a vertical manufacturing footprint including design and manufacturing expertise in custom Automation Assembly Systems such as Fixed Automation, Programmable Automation, Flexible Automation, Ultrasonic Welding and also support services.

Customer Centric

Proactive Sales and Operational Support: Offering continuous dedicated support throughout every stage of the customer journey including the initial steps of preparing proposals, estimates, and quotes ready for corporate review.

Ensuring Customer Confidence: Consistently meeting or exceeding customer needs through tailored automation solutions.

True Partner: Proven ability to bridge the gap between what our customers require and the correct automation and stand alone equipment solution.

Creating custom solutions using proven technology

Accuracy in Getting it Right the First Time: Establishing reliability and trust in our services by ensuring precision and accuracy in our delivered solutions.

Short Delivery Time: Providing custom equipment and automation solutions that meet customer needs of short delivery times through efficiency and adaptability.

Implement Industry 4.0 Through the TA Enterprise Profitability Improvement (EPI) System

Advanced Machine Monitoring Technology: Enable advanced machine and system monitoring technology without the need to add sensors to your legacy or new equipment. Augment your existing machine monitoring installations with real-time high definition data.

Leverage TA Systems Experts: Staying abreast of the latest technological advancements with our expert proficiency in deploying Industry 4.0 & AI solutions.

Low Barrier to Entry, Quick Implementation: Utilize existing PLC data structure and publish prebuilt dashboards.

Enable Industry 5.0: Through the implementation of AI and Machine Learning based on trustworthy big data.

Risk Mitigation Solutions

Mitigating Functional, Technical and Operational Risk: Commitment to our customers success by ensuring the functionality and technical robustness of solutions to minimize risks.

LEADING THE FUTURE OF AUTOMATED ASSEMBLY SYSTEM SOLUTIONS

We Build Customer Confidence by Listening, Understanding and Providing the Right Solution for Each Automation Assembly System Requirement.

LEADING TECHNOLOGY

Maximize Your Profitability with the TA Systems Industry 4.0 Enterprise Profit Improvement (EPI) System

- Unprecedented End-to-End Value Realization

- Increase in Throughput

- Detection of Manufacturing Potential

- Identification of Spare Capacity

- Predictive Process

- Enterprise & Supplier Process Visibility

- Skilled Trade Shortage Mitigation

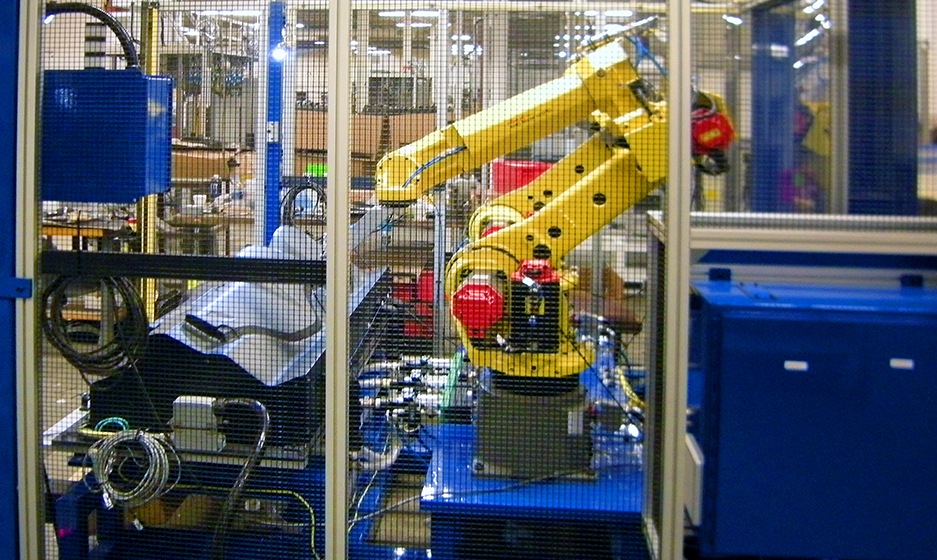

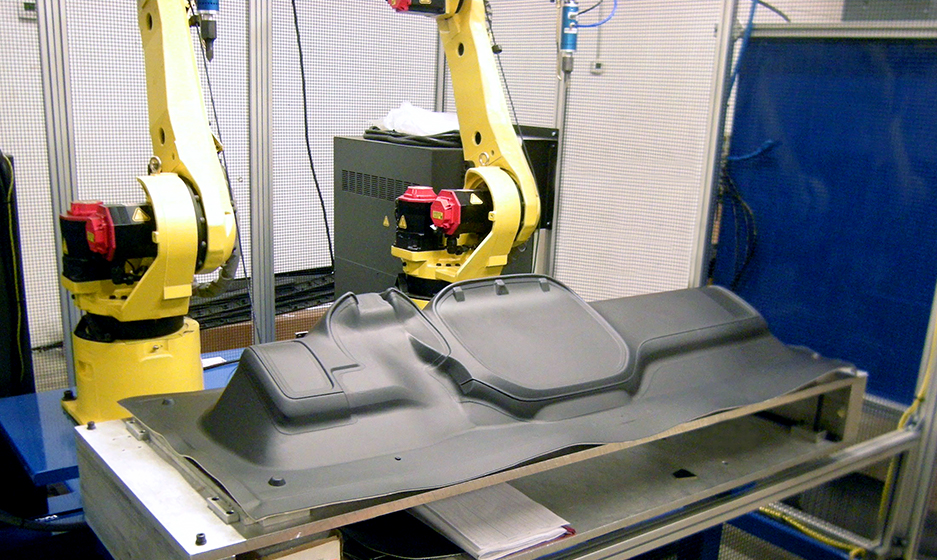

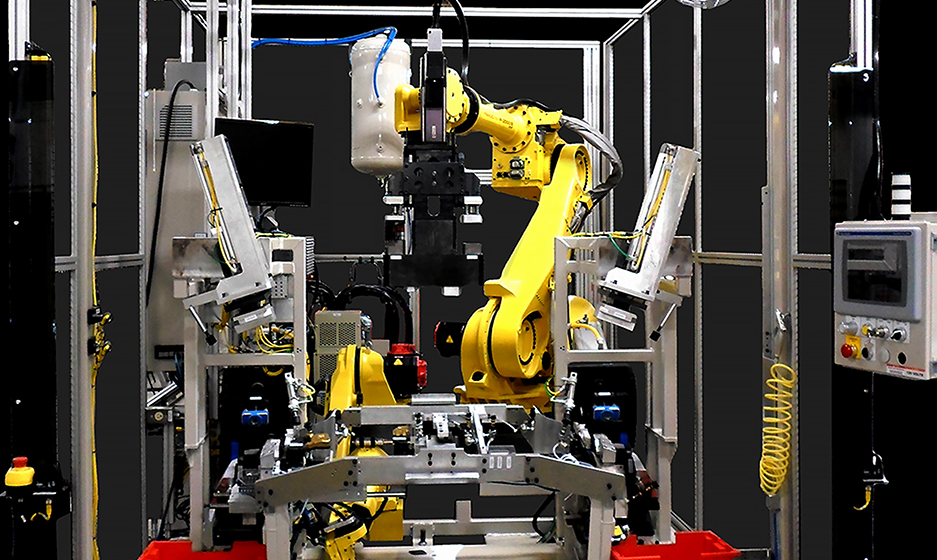

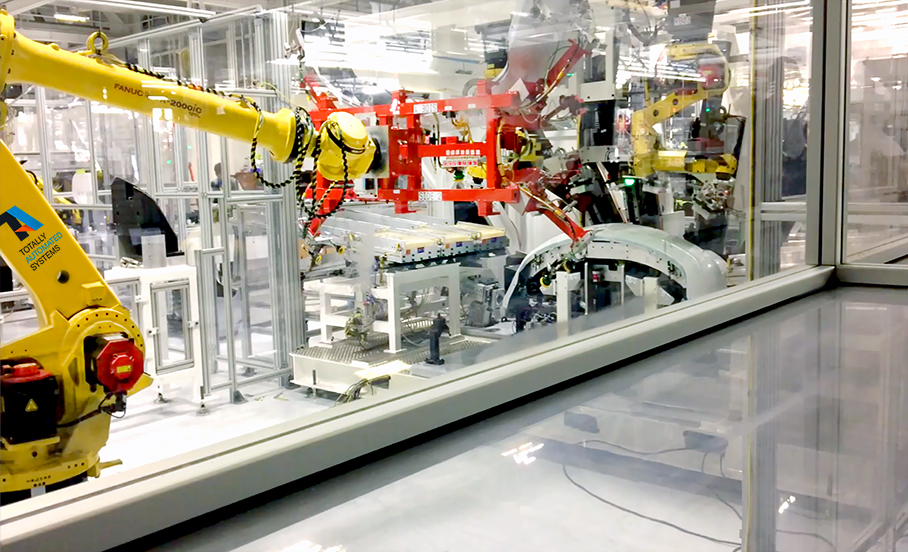

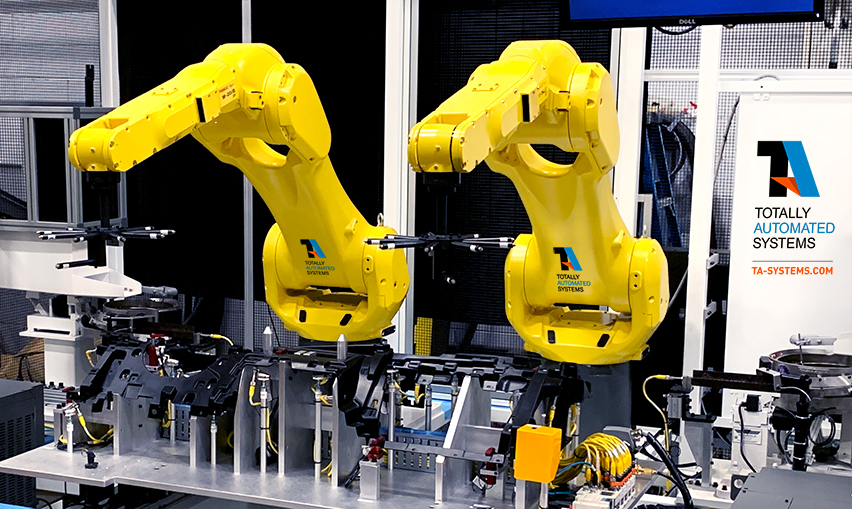

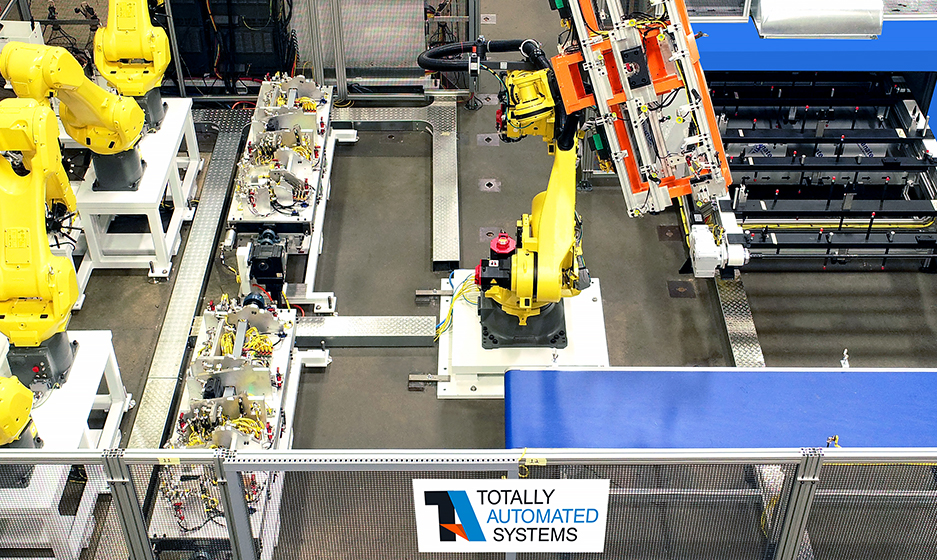

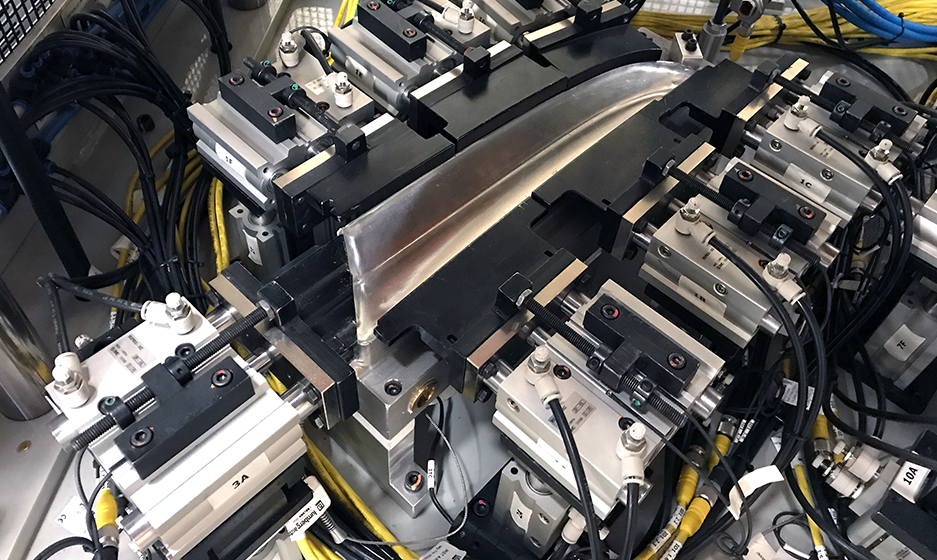

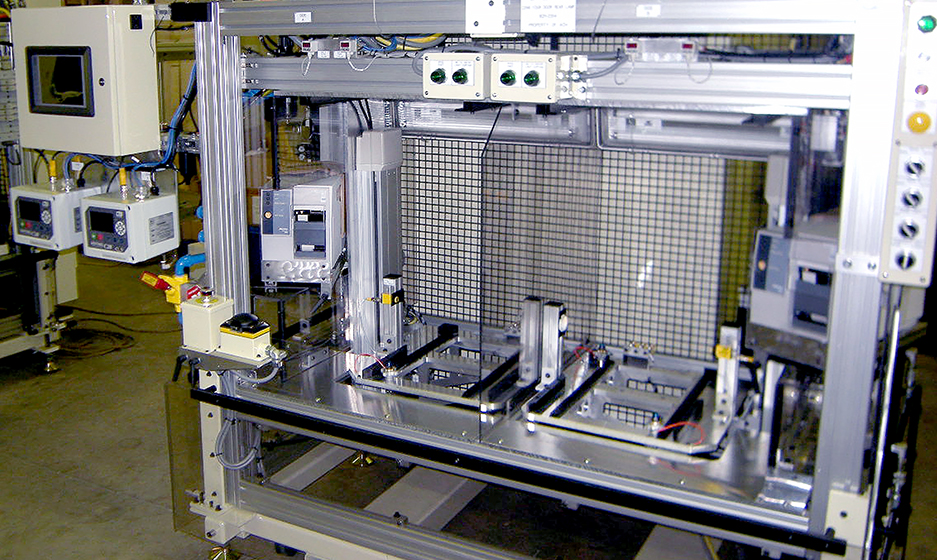

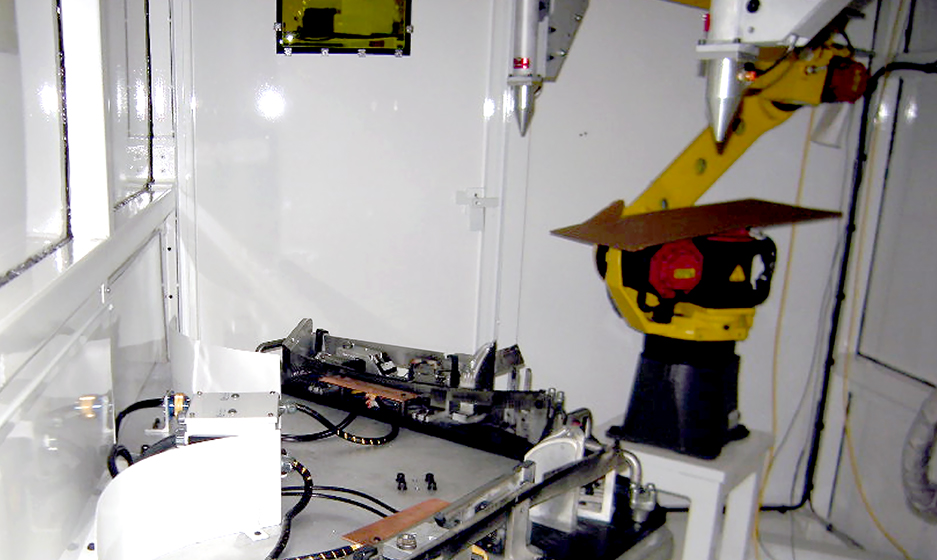

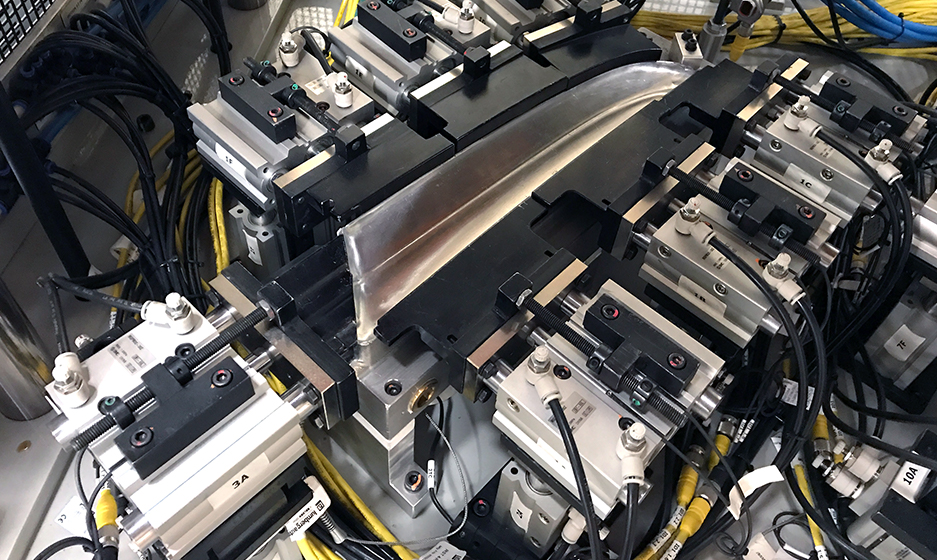

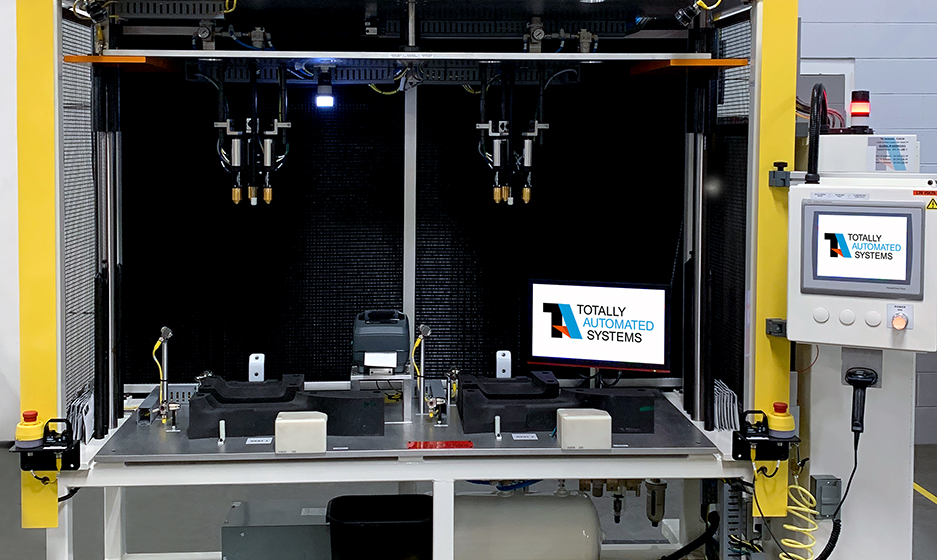

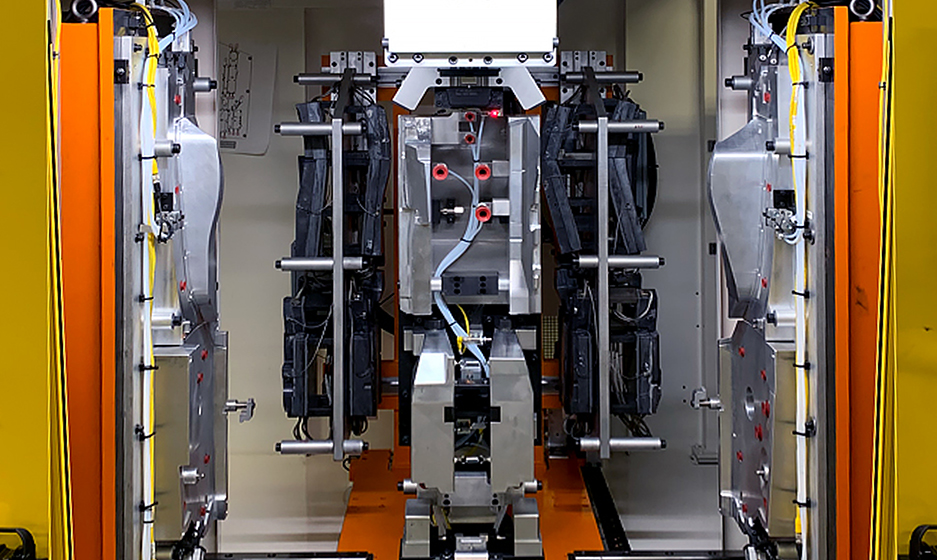

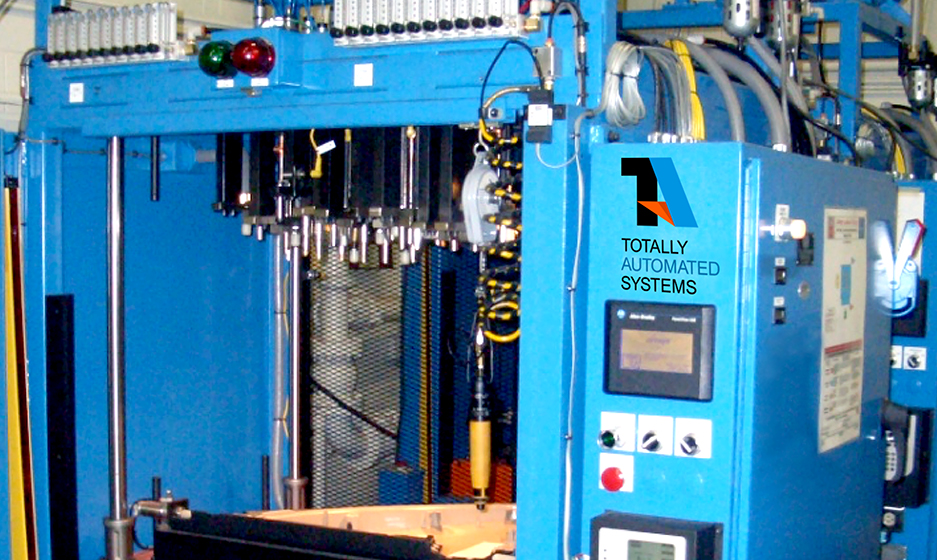

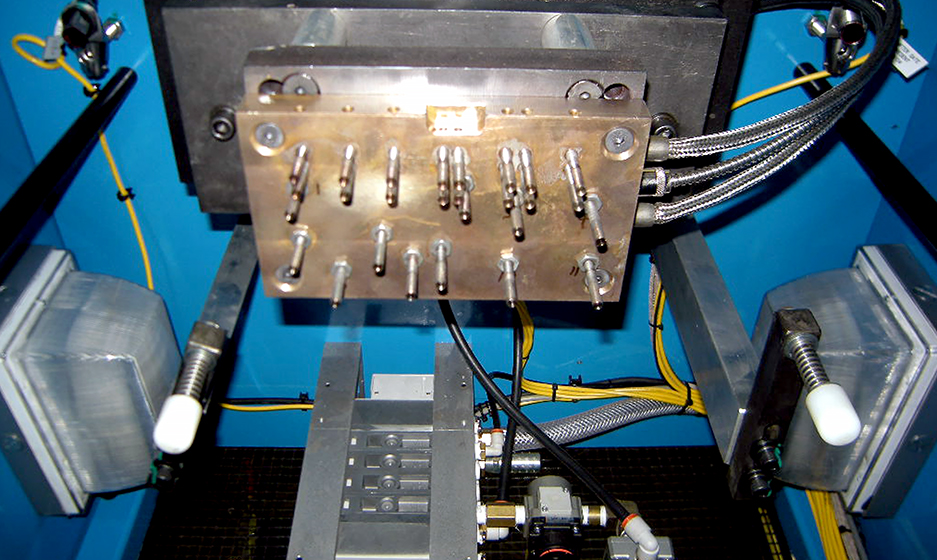

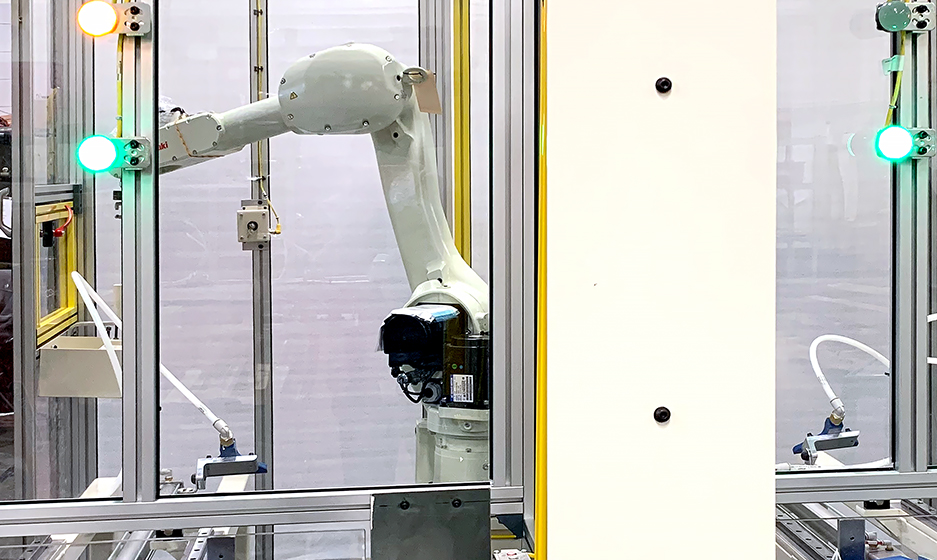

CUSTOM AUTOMATION ASSEMBLY SYSTEM SOLUTIONS

Committed to Leading Innovation by Providing Superior Automated Manufacturing Systems

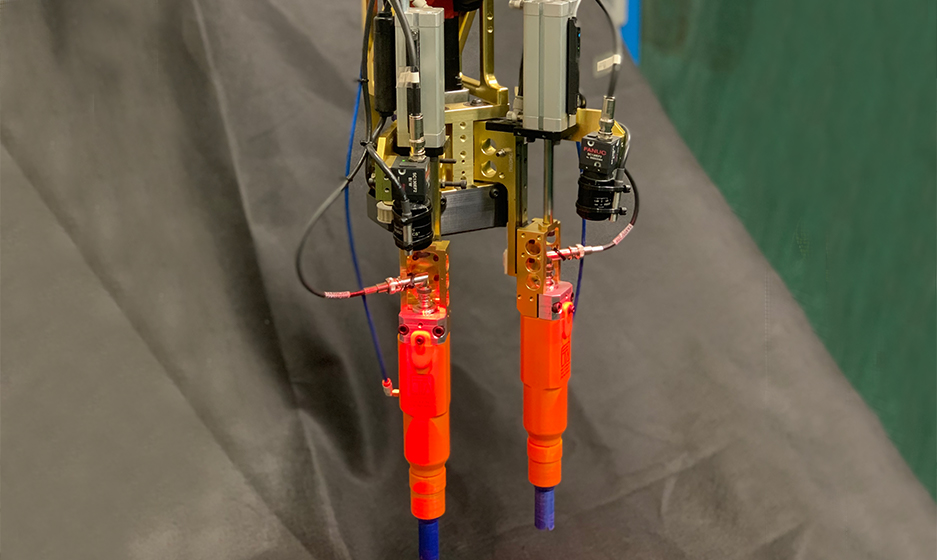

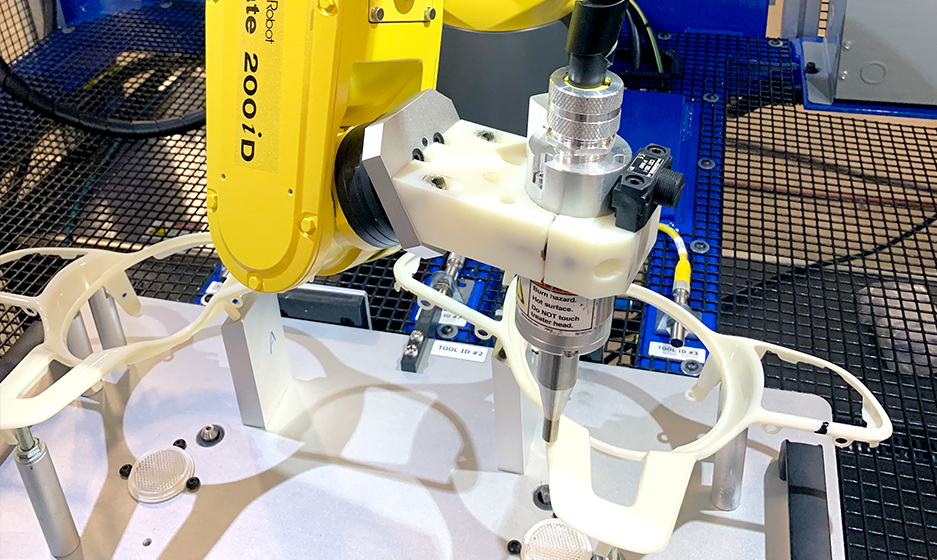

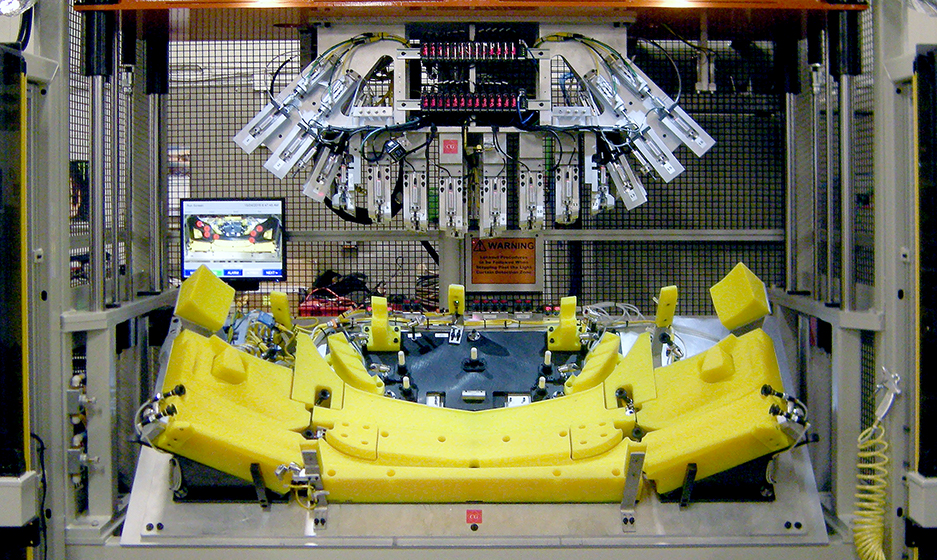

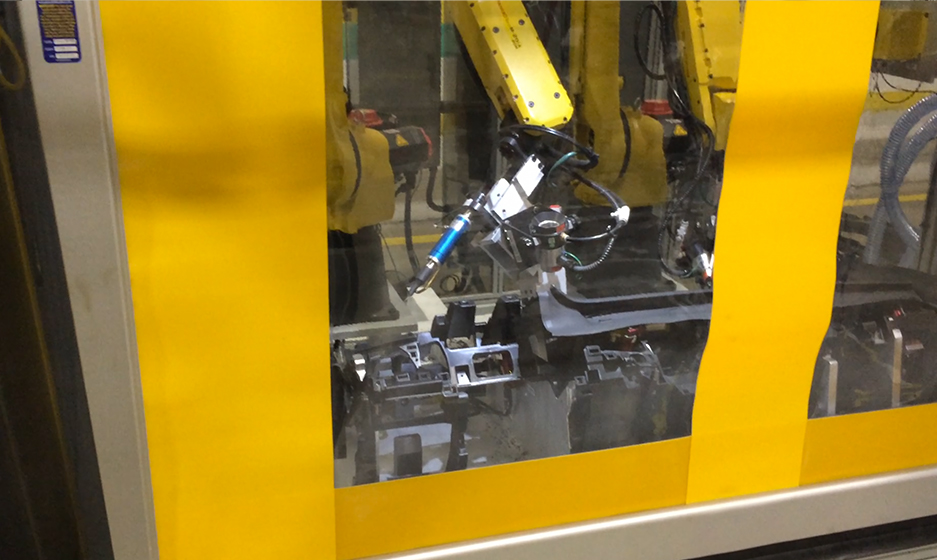

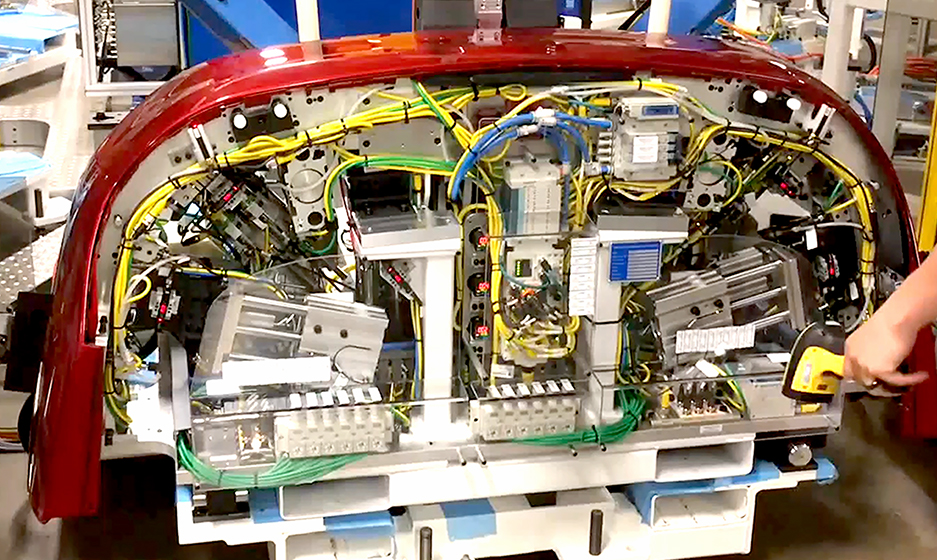

Designing, building and installing custom solutions for over 45 years. Our systems have provided solutions for automated tasks such as: Machine Assembly, Equipment Integration, Material Handling, Vision Processes – 3D Vision, Bin Picking, Mistake-Proofing Inspection and Validation, Fixturing

ACCURATE FAST TURNAROUND TIMES

Experts at Delivering Proven, Accurate, Custom Solutions Fast

- Accuracy and Getting it Right the First Time

- Short Delivery Times

- Quick Project Turnaround Times

LIFECYCLE MANAGEMENT

TA Systems Offers a Holistic Approach to Lifecycle Management

We provide superior after sales Support & Service with continuous dedicated, customer-centric support throughout every stage of the customer journey.

Automated Assembly System Process – How We Work

AUTOMATED SYSTEMS

Our Solutions

Providing Custom Automated Assembly Systems For Your Industry

Testimonials

Thank you guys for your patience and hard work with our Window Urethane project. We have very good reflection on your portion of that project and look forward to our next venture, which I hope will be soon.Please tell your entire team thanks! Your team has once again illustrated that TA System is a “Top Tier” vendor with great skills!

Thank you… your team hit a home run in my opinion on this project. Very pleased with the way the parts looked. Once again…. Thank you for a job well done!

I don’t usually send out “Thank You” emails after a project completion, but this project was different and deserves mention.TA Systems did a fabulous job on the install, programming and training. TA Systems programming has already been sent out as an example to another vendor as a template to follow.

I’d also like to thank you for your project leadership and meeting our exacting standards here at Toyota. Your efforts made it possible to go into production with a fairly complicated piece of production equipment just two days after install. That’s practically unheard of here, due to our rigorous standards. We were able to install and Kanban your equipment with only 9 new punch list items at install. This is the way it should be.

On behalf of Holden we really appreciate the support you and your team offered.What we accomplished in those 2 hours saved Holden weeks.

Thank You TA Systems! Your support and help has been greatly appreciated. Your expertise made it a very easy transition and your software made it even easier to set up. Again, Thank You.

Kyle is a machine! I have been so impressed with his willingness to support in whatever area needed. He is professional, accommodating and knowledgeable. He behaves as a part of the team who shares personally in our wins and losses and this is energizing to me and my team.

Thank you, TA Systems team for your quick response and support!

I want to thank you and your company for allowing Mr. Layne to come out to our facility and walk us through both A-Pillar & Package Tray Machines. I was quite pleased with his knowledge and command of both machines. His patience with our team was impeccable. He was a pleasure to work with. Please let him know on behalf of D-V, Thanks.

Excellent First Time Through Results!

All is well and so far, so good. Thank you guys for your support and help with this. It has been greatly appreciated. It was actually a very easy transition and the software made it very easy to set up.Again, Thank You.